Finishing the Mounting of Devices on the Underside of the Playfield

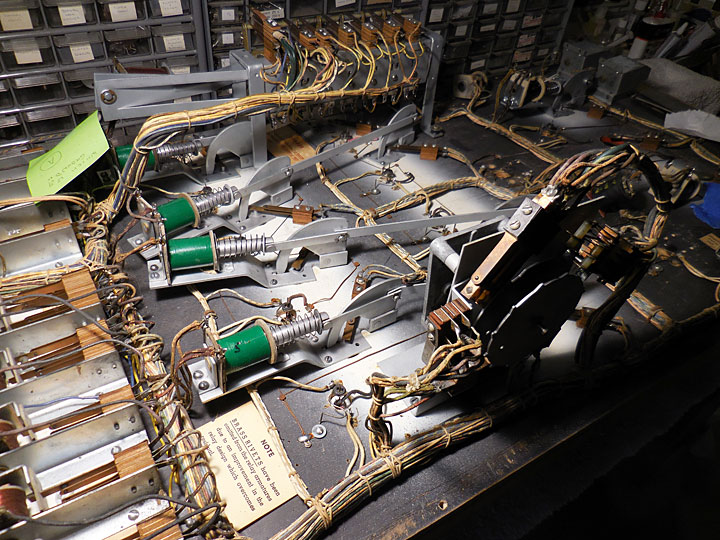

The upper part of the playfield devices are finished. The eject mechanisms with the green solenoids are all mounted. The reset bank has been installed and the stack switches mounted and adjusted. The relays on the left have all been adjusted. Finally the motor driven increment mechanism has been installed and its switches attached.

So what are all these adjustments? The stack switches consist of metal leaf material with contacts riveted to the ends. I straighten all the metal leaves and burnish the contact material. You should never burnish a modern leaf switch as it will remove the gold plate. Old switches like these need to be burnished. In addition there are some high current contacts that are pitted because of the arcing. These should be filed down using a contact file like the ones used in old auto ignitions.

The stacks shrink over time and loosen the mounting screws. You should tighten the stack even if you do not remove it as I have done.

Relay contacts should be adjusted so that they clean themselves. This is accomplished by setting the gap at 1/16 of an inch and then making sure the action causes the moving leaf to go past contact and bend the stationary leaf just slightly. This wiping motion removes any corrosion that might form.

This picture shows the amazing color balance of my new light emitting diode (LED) light. I purchased extra while building a cabin in Idaho. I brought the remaining lamps home and installed one in my articulated arm light over my work bench. It runs cold so I can touch it to adjust and best of all, the camera likes the color rendition. These are 2700K color temperature. I prefer 3000K, even whiter, but my wife likes the warmer color as it is closer to incandescent colors.

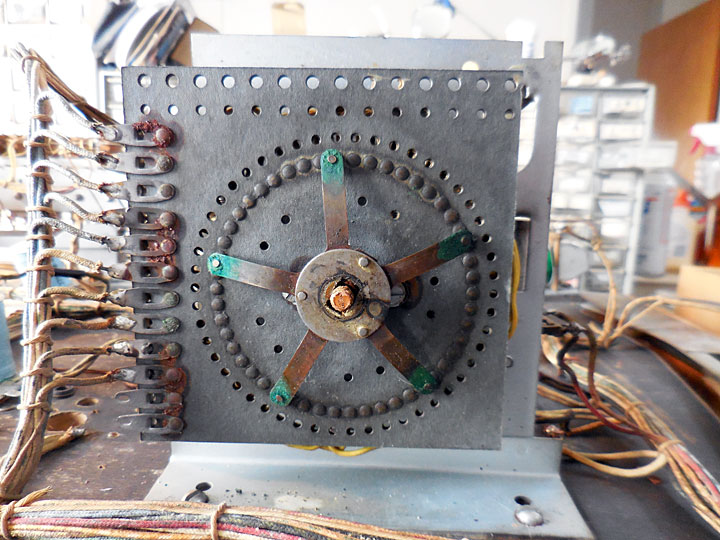

This is the selector mechanism. It increments the selected horse so that any advance pumper for that horse moves the horse if contacted. It is in sad shape. The corrosion on the fingers is caused by using an old lubricant, most of which are acidic in nature.

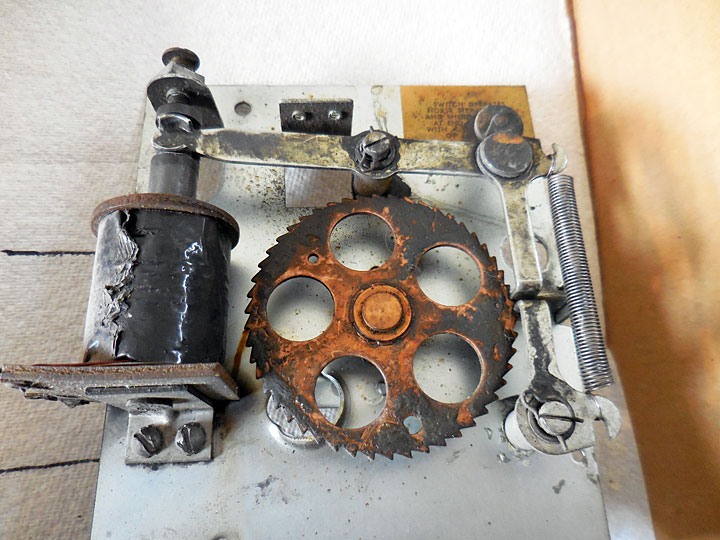

Here the acid lubricant has caused significant rusting.

The back side of the selector mechanism shows significant dried lubricant damage. It would not even turn.