proActive is the official industry newsleter of Lotus Engineering. This is issue 3, July / August 2004

Features

Campro: A Worldwide project

Taking the Elise to America

Global Engineering: Myth or reality?

Logan: Renault's 'world car'

Regional perspectives

News

Jaguar's new V6 diesel impresses

SWITZERLAND: Cina is the new competitive reality according to Lutz

SWITZERLAND: European car makers demand less regulation

TI to introduce revolutionary fuel pump to meet the needs of modern GDi systems

Taking the Elise to America

The Elise was first introduced to the European market in 1996 changing the rules in the design of new cars. The Elise proved that it wasnât necessary to build a large and heavy car to meet ever more stringent safety legislation and underlined the benefits to performance, fuel economy and emissions of a low mass approach. Now, Lotus has successfully launched the latest variant of the Elise into the ultra-competitive Federal market for the first time, with customer deliveries starting in July.

A major exercise was undertaken to understand exactly what would be required to meet both market expectations and the demands of Federal vehicle legislation. Ultimately, a large proportion of the vehicleâs components were revised during the design and development process, including the powertrain, the fuel system and the interior.

Despite exceptional performance of the original Elise through its light weight, Lotus understood that for the Elise to be a commercial success in the USA the power output of the engine would have to be greater than that achieved by the Rover Kseries engine. In addition, the Rover unit had not been homologated for the States and its more stringent Federal exhaust emissions regulations, and it would have proved a significant and costly exercise. These factors led Lotus to seek a new powertrain for the car, and after assessing a range of options, the decision was made to install the elegant 190bhp Toyota 2ZZGE engine from the Celica GTS.

Although the Toyota powerplant was already fully approved for Federal use, Lotus elected to use a bespoke Engine Management System, developed in-house, to ensure it was tailored to perform as desired in the Elise, a far lighter car than its donor. This decision effectively defined the critical path for the programme timing, with the very first prototype cars being built for calibration development work and the very last activities on the programme being the final approval of the vehicle by the US Environmental Protection Agency. This whole process ran to schedule and took just 16 months to complete.

Federal evaporative emissions legislation required a complete redesign of the vehicle fuel tank and associated systems, presenting a major challenge in terms of being able to accommodate the necessary systems within the available space. In addition, the opportunity was taken to increase the fuel tank capacity and revise the tank construction to use stainless steel.

The interior of the car was completely renewed, primarily to enable the inclusion of both driver and passenger airbags to meet Federal unbelted occupant requirements. Tests confirmed that the Elise offered a high level of occupant protection. This is attributed to its exceptionally stiff aluminium tub chassis, combined with the innovative composite crash structure, aluminium door bars and steel seat belt anchorage frame. In addition, a programme of NVH development within the vehicle structure has also achieved a greatly improved level of comfort within the cockpit.

The Elise required little more than the addition of front airbags to meet the Federal safety requirements as the existing structure provided excellent test results in side impact, rear impact and roof crush tests. The driverâs airbag is neatly contained within the hub of an ergonomic Momo sports steering wheel, while the passenger airbag is unobtrusively positioned behind a tethered door in the facia trim. The increased manufacturing volume of the car justified the use of injection moulding to manufacture the majority of the plastic trim parts rather than vacuum forming as has been used previously on the Elise, with a commensurate improvement in quality.

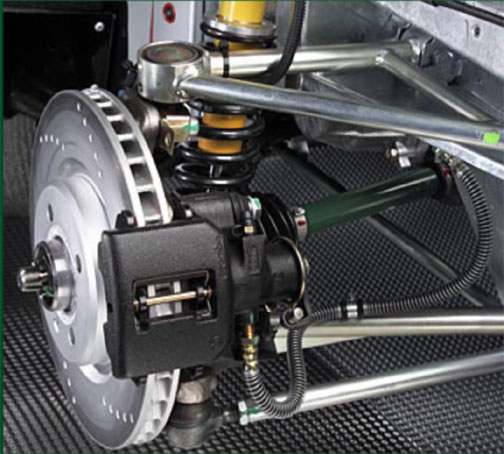

The Elise has always been quite rightly famed for its exceptional ride and handling capabilities; compromising this key characteristic was entirely out of the question. Brand new bespoke Yokohama Advan Neova AD07 tyres have been developed in parallel with unique spring and damper settings to not only maintain but improve on the high standards set previously by the European version of the car. A number of tyre submission tests were performed, each one reviewing a range of different construction and compounds and deciding the specifications to be assessed at the next test. In addition to the standard suspension there is also a Sports suspension option which is aimed squarely at the track day enthusiast or club level race competitor. This offers increased rate springs and revised damper settings plus a set of wonderful ultra-lightweight forged aluminium wheels and high performance Yokohama A048 sport tyres. The sports suspension option offers the ability to pull lateral âgâ levels which would put many a race car to shame.

The new powertrain offers a power delivery characteristic which perfectly suits the sporting nature of the Elise, with unusually high peak power and torque speeds. A more conventional engine would normally achieve its peak torque at a lower rpm. This encourages the driver to utilise all of the engineâs speed range and together with the precise shifting close ratio six speed gearbox produces a driving experience which is not only fast but feels fast too, bringing the fun back into driving at sensible speeds.

The total programme took just over 16 months from initial concept approval to start of production and involved 33 prototype vehicles for the Federal programme in parallel to the simultaneous programme which introduced a Toyota engined Elise to the existing non-Federal markets. The design and development team was organised on a cross-functional basis with a core team of 5 Release Engineers, a Development Manager and a Supply Chain Manager all reporting to the Chief Engineer, Malcolm Powell. Each of these function leaders controlled a team drawn from the resources within Lotus Engineering. At the peak of the programme the direct team totalled approximately 60 members.

The success of the programme is self evident, with Lotus currently having firm orders for more than the first year of production of the Federal Elise even before demonstrator cars had been delivered to dealers. The car was formally launched at the 2004 Los Angeles Auto Show where it won the unofficial accolade of âmost exciting car of the showâ and the Lotus stand was besieged with thousands of visitors every day.

The introduction of the car to the dealers and the press was held over a three-day period at Barber Motorsports Park near Birmingham, Alabama in March 2004. Press reports from the event rate the car as one of the most exciting road vehicles available at any price, and draw direct comparisons with other illustrious marques such as Ferrari and Porsche.

Having fully tested the Eliseâs supercar-challenging performance and understood the exceptional fuel economy and low environmental impact that its low mass makes possible, one major sports car magazine felt compelled to ask the question âIs this the most significant new car to come to America this year?â

Source: Nick Adams, Lotus Engineering