ProActive Magazine from Lotus Cars

proActive is the official industry newsleter of Lotus Engineering. This is issue 8, May / June 2005

Features

Powertrain testing - from concept to production

Powertrain developments

The drivers for automotive engineering

Lotus engine controllers

News

Germany: Auto industry is worried about meeting CO2 targets but praises London's congestion charging

Germany: Bosch produces first throttle body in composite material

Tightening NOx emission rules could boost hybrids at diesels' expense says Lexus

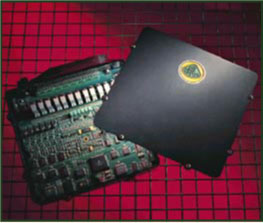

Lotus Engine Controllers

Lotus V8 controller

Lotusâ need to create its own bespoke controller started with the introduction of the Lotus Esprit V8 destined for the US market. The low production volumes made it difficult to find a supplier from the established Tier I suppliers.

The solution for Lotus was to team up with a specialist supplier with a background in producing ECUs for motor sport, including Formula 1, and ultra low volume cars.

Lotus Engineering worked with the supplier to produce a bespoke controller enabling the 350hp 3.5 Litre V8 twin-turbo to meet Federal Tier I and CARB TLEV emissions, and provide OBD II diagnostic functionality.

Using Lotus Engineeringâs experience in software, algorithms, diagnostic strategies and calibration, along with its supplierâs experience in hardware design and control systems, the Lotus Esprit V8 launched in 1996. This was the start of a long and successful relationship between the two companies.

This controller was then adapted to control special vehicles derived from the Elise; the Lotus 340R and the Lotus Exige with 179PS and 195PS versions of the Rover K Series engine.

Lotus K4 controller

The next step in the evolution of the Lotus controllers was on the Lotus Elise with the Rover K-Series engine. Although the original Elise was launched with the Rover MEMS engine controller, the introduction of Euro III and EOBD legislation in 2000 required a new controller calibrated specifically for the Elise.

Again working with the same supplier, Lotus Engineering developed a bespoke controller that was interchangeable with the Rover MEMs controller. The Lotus K4 controller has been used on all variants of Lotus cars using the Rover K-Series engine from 2000, which include:

- Standard Elise Elise

- 111S Elise

- 135R

- Elise Sport 190

Lotus T4 controller

With the launch of the Elise into the US an alternative engine was needed. The chosen engine is the high performance 2ZZ-GE engine from Toyota.

Again due to the low volume, the existing engine controller could not be used. This led to the creation of a new controller specifically for the Toyota engine - the Lotus T4 controller.

The installation of the Toyota engine was completed for the Euro IV and US markets in 15 months and 19 months respectively in 2004/5.

Lotus T4e controller

The development of the Lotus controller is ongoing and the T4e controller moves the technology forward significantly and will enable future models to meet LEV II.

Along with the introduction of the electronic throttle control for the Toyota engine, the controller is now based off a state of the art Power PC architecture allowing much faster operation.

R & D controllers

The use of Lotus controllers has not been limited to Lotus products but has also been a major tool in Lotus Engineeringâs powertrain research and development programmes for third parties.

Due to the strong working relationship between Lotus and the supplier, and with Lotusâ ability to write the software and algorithms in house, Lotus controllers have been adapted to run a wide variety of engines. This approach saves both time and money on special development programmes.

Below are some examples of R&D applications for Lotus controllers.

Cylinder deactivation demonstrator

A Lotus V8 controller has been used for two development programmes to evaluate the benefits of cylinder deactivation on V8 engines for North American clients. All the control strategies and software were developed in house by Lotus Engineering.

CNG demonstrator

Due to the flexibility of the Lotus V8 controller, this was the basis for the controller used for the Lotus Elise CNG demonstrator. A single controller was used to control the gasoline and CNG fuelling.

Gasoline direct injection demonstrators

Gasoline experience is not limited to port injection with a Lotus controller being used for the much more precise fuelling requirements of GDi engines. Again, the software and algorithm development was carried out by Lotus.

Performance demonstrator

For a client wanting to produce a one-off performance demonstrator in 9 months, the Lotus T4 controller was the perfect solution.

Packed with performance enhancing features, the engine was up-rated by Lotus from 145PS to over 200PS. The features controlled by the Lotus controller included intake and exhaust cam phasing, cam profile switching and a variable intake manifold.

Prototype V6

For a new family of V6 engines being developed by Lotus, a new state of the art controller was developed, the Lotus N6.

Being developed for LEV II and OBD II compliance, this controller has formed the basis for the Lotus T4e controller to be used on the LEV II Elise.

The high feature content of the Naturally Aspirated and Supercharged engines makes the Lotus N6 controller suitable for most gasoline engines up to 6 cylinders.

The V6 family includes features such as:

- 4 cam phasers

- 4 stage variable intake manifold 6 ignition coil drivers

- 4 lambda sensors

- 2 knock sensors

Diesel engine development

Showing the flexibility of the Lotus controllers, with a minor hardware change, the Lotus N6 control is currently running a V8 diesel engine. The controller has been adapted to control electronic throttle, oxidation catalyst, particulate filter, de-NOx catalyst and exhaust fuel injection.

From receipt of the specification from the client, the engine was running on the revised Lotus controller in just five weeks.

Lotus R & D

In addition to supporting client programmes, Lotus controllers have been used to support Lotusâ own research and development. For example Lotusâ patented Single Lambda Sensor OBD II control system was developed using the Lotus V8 controller, and of course, Lotus controllers are used on the Active Valve Train research engines.

What next with Lotus controllers?

The potential for Lotus controllers is huge. With the T4e and N6 controllers, Lotus has two state of the art controllers capable of meeting the most stringent emissions and diagnostic requirements for high feature I4 and V6 engine applications at low to medium volume.

In addition to the potential associated with production engines, the hardware flexibility and in house software and algorithm development means these systems are ideal for any R & D opportunities. This is especially true where flexibility, speed and cost are important to the customer.

As well as developing the hardware and software, Lotus Engineering has also been developing its processes. By using Mathworks Simulink, Lotus is now designing and developing algorithms faster than ever with the auto-coding functionality further reducing the time to first engine run.

For the existing production controllers, Lotus is also investigating low cost high volume manufacturing opportunities. With the move in the developing markets towards Euro III and Euro IV emissions levels with EOBD on board diagnostic requirements, Lotus sees huge potential for its Euro IV capable controller.

Backed up by an experienced team, who can tailor the hardware, software and calibration to suit a particular customerâs requirements, a Lotus controller is a very attractive and versatile proposition.